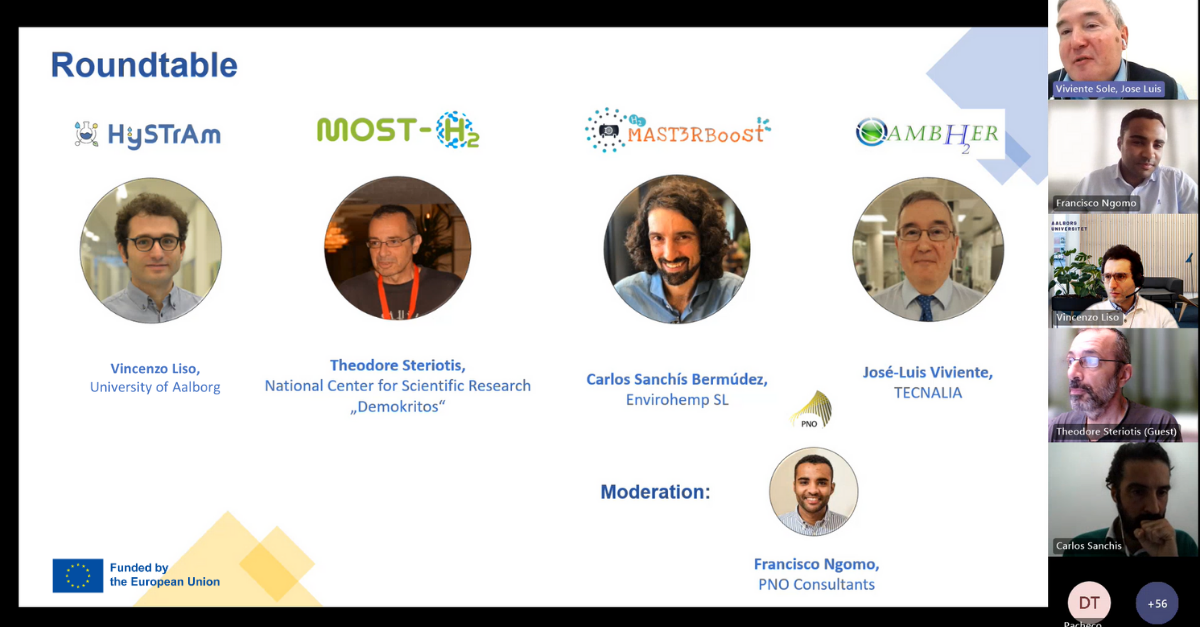

First HySTrAm clustering event together with MOST-H2, AMBHER AND MAST3RBoost projects!

December 4, 2023

Watch the full event and enjoy the discussion!

The HySTrAm first clustering event titled “Next generation of hydrogen storage solutions based on innovative materials” was held in conjunction with MOST-H2 and supported by Mast3rboost and Ambher projects. The event showcased an array of promising hydrogen storage technologies investigated by esteemed research institutions and industry leaders across Europe.

Europe is positioned to spearhead the global drive towards becoming the first net-zero continent by 2050. To achieve this ambitious objective Europe needs to adopt cutting-edge, emission-free fuels to produce clean energy and propel sustainable transportation forward. Hydrogen, recognized for its superior calorific value and eco-friendly combustion, stands out as a frontrunner in the pursuit of carbon-neutral fuels.

Although hydrogen holds immense potential, its deployment and widespread adoption as a fuel encounter a crucial hurdle: storage. Present methods involve high-pressure tanks or cryogenic temperatures, leading to notable concerns regarding cost, safety and feasibility. However, innovative approaches such as the use of green ammonia produced through the Haber-Bosh process or Hydrogen adsorption onto ultraporous solid supports present promising solutions to this significant bottleneck. These techniques offer storage options that alleviate the stringent conditions currently necessary for hydrogen storage, addressing key challenges in its deployment.

In this context, the event aimed to showcase the current progress of innovative materials, developed by these four EU-funded projects, for the upcoming generation of hydrogen storage solutions. The event proceeds with a series of presentations beginning with Vincenzo Liso, Coordinator of the HySTrAm project that aims to develop innovative solutions to produce green ammonia from hydrogen at lower pressure, thereby making the process more efficient. Vincenzo Liso explained the different approaches to store hydrogen: directly, as H2, or indirectly, as NH3. The selection between the two options relies on the specific requirements and limitations of the intended application. When deciding, several crucial factors come into consideration.

Indirect ammonia-based storage, on one hand, may require additional steps involving the synthesis and dissociation of ammonia. However, it proves to be more cost-effective for long-distance transport and storage, thus becoming a preferred choice for particular applications. On the contrary, the superior energy density of ammonia, especially by volume, makes it more attractive for scenarios where space limitations are a concern. Direct hydrogen storage becomes advantageous in situations where rapid release and high-pressure storage are pivotal. Moreover, choosing between direct and indirect storage methods is contingent upon the precise requirements of the application at hand.

The HySTrAm project aims at developing innovative solutions to produce green ammonia from hydrogen at lower pressure, thereby making the process more efficient. The consortium is currently finalising the detailed system design while awaiting the final experimental results to fine-tune both the design and system control. At present, the project is on schedule to initiate the procurement of components for the construction of the pilot plant where they will produce ammonia. Vincenzo Liso emphasised the upcoming pivotal phases of the project, marking the transition into its final stages. This includes the development of the Metal-Organic Frameworks (MOF) for hydrogen storage, ammonia synthesis catalyst, and ammonia absorbent. Simultaneously, the team will proceed to finalise the construction of the pilot plant and conduct the conclusive round of testing at Anwil S.A, company based in Poland.

Meanwhile, the MOST-H2 project is developing monolithic MOF adsorbents with an optimal combination of volumetric and gravimetric capacity. The targeted materials can store hydrogen efficiently and as a consequence, it will be easy and safe to transport having a small environmental footprint. The consortium comprises the IMMATERIAL company specialising in the large-scale synthesis of MOF monoliths. Their expertise will support the project’s aim to scale up the synthesis of the selected MOF materials to a minimum of 10kg. Theodore Steriotis, coordinator of the MOST-H2 project, stressed that the economic viability of their material development and upscaling approach will be comprehensively evaluated through rigorous LCA (Life-Cycle Assessment) studies, including Life Cycle costing analysis and Life Cycle Sustainability assessment. Additionally, these studies will be complemented by an exhaustive Techno-economic analysis specifically tailored for applications in the transport sector.

In this framework, the AMBHER project is also working to develop its main activities around ammonia synthesis for long-term storage and novel nanoporus MOFs for short-time storage. Meanwhile, the project is simultaneously developing and demonstrating innovative and more cost-effective compressed hydrogen storage solutions. This initiative holds the potential to bridge the gap towards establishing local and economically significant power-to-hydrogen hub. José-Luis Viviente, coordinator of the project, emphasized the significance of enhancing the manufacturing readiness level of materials and components, along with raining the Technology Readiness Level (TRL) through extended testing periods or larger demonstration units. According to José-Luis, in this scenario, the AMBHER consortium already comprises industrial partners capable of scaling up material production, along with partners ready to establish spin-off companies when necessary.

As an alternative to MOFs, the MAST3Rboost project based on a new generation of Machine Learning-improved ultraporous materials such as Activated Carbons (ACs) and high-density MOFs . This will enable a disruptive path to meet the industry goals by developing the first worldwide adsorption-based demonstrator at the Kg-scale. The primary distinction between ACs and MOFs lies in the nature of their porosity. On the one hand, nearly all pores of the MOFs are uniform and typically converge around 1 or 2 main pore sizes, resulting in an exceptionally narrow pore size distribution. On the contrary, the ACs are a single material that can encompass a diverse range of pore sizes that amalgamate to create a distinctive fingerprint of the pore size distribution. Unlike MOFs, this inherent characteristic of ACs presents challenges in achieving a uniform porosity. Building upon this, the Mast3rboost project is developing new approaches to produce ACs within the range of 3000-4000 m2/g, aiming to significantly reduce pore broadening mechanisms.

According to Carlos Sanchís, coordinator of the MAST3TRboost project, this advancement will empower AC materials to effectively compete with MOFs in the complete range of BET surface area. Through this process, the MAST3RBoost aims to expand the array of available adsorbent materials, offering novel combinations of “Surface area-Pore volume” that are currently unavailable in MOFs. After successfully replicating the most efficient lab-scale ACs at a multi-kilogram scale, the project anticipates achieving a viable H2 storage surpassing 50 gH2/l at the material level.

In summary, the experts analysed the existing European regulatory bottlenecks concerning hydrogen applications and storage. They unanimously advocated the need for a unified European legal framework stands as a crucial step to effectively implement hydrogen technologies in practical applications across the market. Moreover, the cost factor to enter the market as well as the societal acceptance of ammonia as a hydrogen energy carrier might pose a significant concern in this regard.

Check out all the presentations:

- HySTrAM project: Hydrogen Storage and Transport using Ammonia

- MOST-H2 project: Novel metal organic framework adsorbents for efficient storage of hydrogen

- AMBHER project: Ammonia and MOF Based Hydrogen StoragE for euRope

- MAST3RBoost project: Next generation of hydrogen storage solutions based on innovative materials

SHARE ON

SHARE ON