Why is HySTrAm developing MOF materials for short-term hydrogen storage?

May 17, 2023

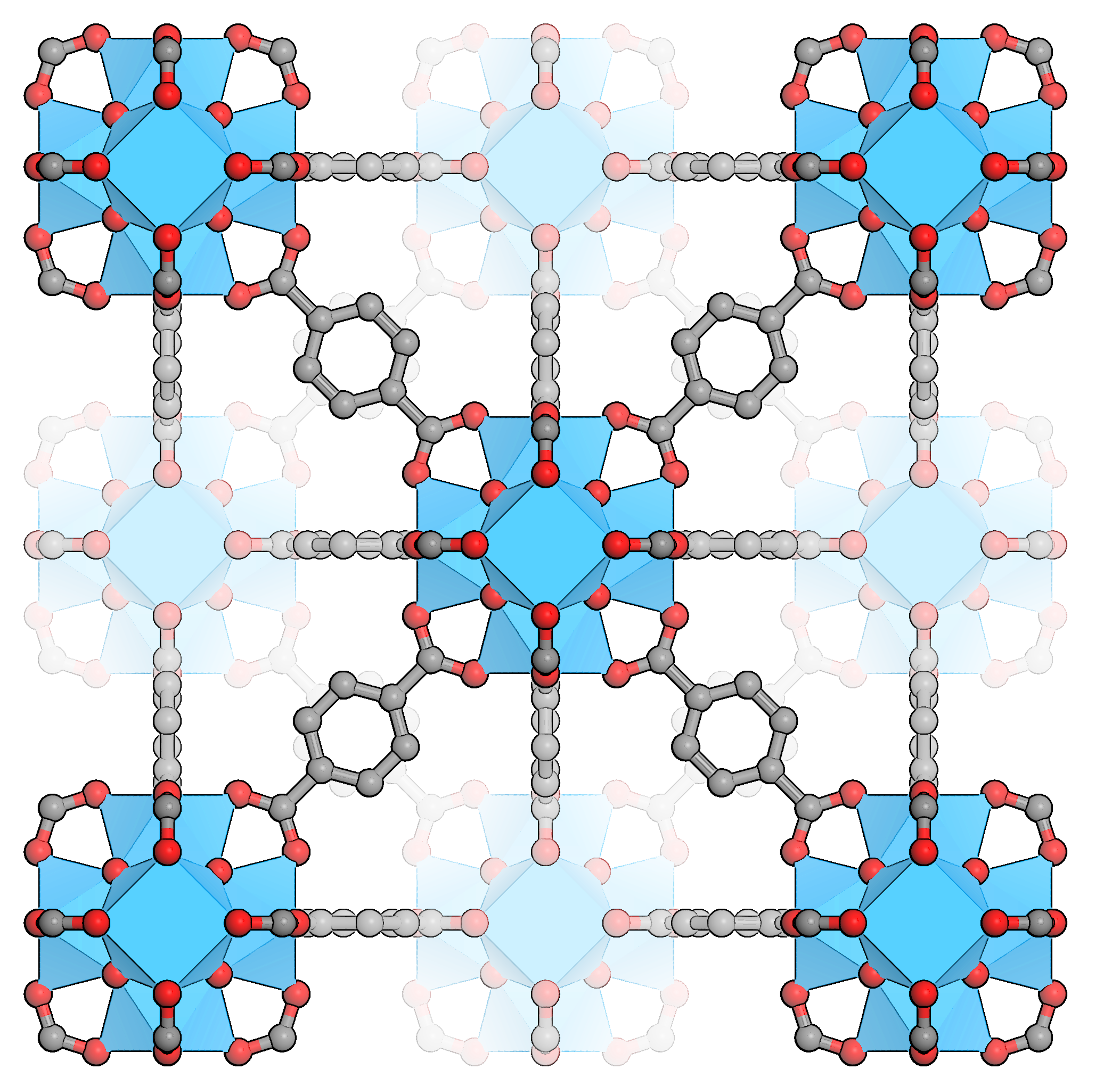

Structure of zirconium MOF UiO-66

Over the last twenty years, Metal Organic Frameworks (MOFs) have been the subject of intense research worldwide. The unique properties of the reticular chemistry of MOFs propagates diversity. Combining a wide variety of metals with the endless diversity of organic molecules, tens of thousands of materials have now been made and hundreds of thousands more remain yet possible.

The reason for this extraordinary level of commercial and academic interest in this class of materials is clear. The combination of open, ultrahigh surface area frameworks with the possibility of functional properties of organic molecules opens the door to a wide variety of possible commercial applications including adsorption, catalysis, gas- and liquid-based separations, sensors, and even pharmaceuticals. Although these applications are all areas of intense research efforts, perhaps chief amongst them in terms of immediate commercial viability are gas adsorption and storage applications that utilize the native ultrahigh surface area and pore volumes of MOF materials. Some MOFs are already at or near commercial availability for certain gases such as hydrocarbons.

Improved storage solutions for hydrogen gas are critical for development of green energy systems and the hydrogen economy. Due to the physical properties of hydrogen gas, the existing technologies require large, and therefore costly, energy inputs for compression and/or cryogenic cooling. MOFs present an opportunity for a radically alternative approach to storing hydrogen gas by taking advantage of energetically favorable adsorption within the porous frameworks of the MOF. Such adsorption based storage systems will enable greater quantities of gas to be stored in smaller volumes and at lower pressures than otherwise required for compression and storage of hydrogen, lowering both infrastructure costs and, critically, energy use.

As the world leader in development zirconium based MOFs, ProfMOF was among the first actors bringing commercial MOF products to market. The unique ultrahigh stability of zirconium based MOFs have made them perfectly suitable to integration in commercial applications that require not only the functional properties of the MOFs but extreme durability under difficult conditions often found in industrial processes such as wide swings in temperature and pressure. Furthermore, ultrastable zirconium MOFs may be integrated into processes in which cycling though extreme conditions are required without degradation and maintaining their original properties over time, lowering cost.

The HySTrAM project has enabled ProfMOF to engage with development of proprietary MOF materials for short term hydrogen storage, taking advantage of the ‘tuneable’ flexibility of MOF systems in the context of a commercially relevant concept for the storage of green hydrogen after its production. Critical to the success of the project is the fruitful collaboration between ProfMOF and other consortium members. Most notably Gas Vessel Production, who are providing innovative pressure vessels for hydrogen storage and VITO, which has contributed to the development of material shaping techniques suited to the purpose of hydrogen storage.

ProfMOF looks forward to contributing to the hydrogen economy with the further development and commercialization of innovative MOF based hydrogen storage materials as the HySTrAM project reaches its goals and short term hydrogen storage systems for ammonia production are brought to market.

SHARE ON

SHARE ON